What is a switching power supply

Switching power supply is a power supply that uses modern power electronics technology to control the time ratio of switching on and off to maintain a stable output voltage. Switching power supplies are generally composed of pulse width modulation (PWM) control ICs and MOSFETs. With the development and innovation of power electronic technology, switching power supply technology is also constantly innovating. At present, switching power supply is widely used in almost all electronic equipment because of its small size, light weight and high efficiency. It is an indispensable power supply method for the rapid development of today's electronic information industry.

According to the input and output type of switching power supply, it can be divided into: AC-DC, DC-DC, DC-AC, etc.

The role of switching power supply, such as AC-DC power supply:

Rectification: Convert the input AC signal to DC signal;

Voltage conversion: output the required voltage amplitude;

Filtering: smooth the input rectified voltage;

Adjustment: control the output voltage to make the amplitude constant;

Isolation: electrically isolate the input and output parts;

Protection: Prevent harmful voltages such as surges from reaching the output part and cause equipment damage.

Switching power supply products are widely used in industrial automation control, scientific research equipment, LED lighting, industrial control equipment, communication equipment, electrical equipment, instrumentation, medical equipment, semiconductor refrigeration and heating, air purifiers, electronic refrigerators, liquid crystal displays, LED lamps, communications Equipment, audio-visual products, security monitoring, computer cases, digital products and instruments and other fields.

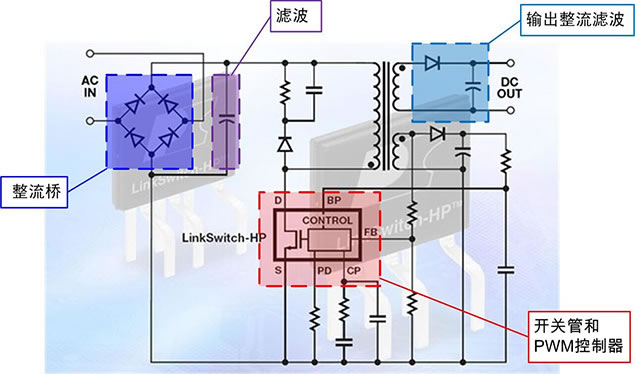

A typical AD-DC switching power supply structure is shown in Figure 2 above.

After the input AC power enters the power supply, it is first rectified by the front-stage rectifier circuit, and then rectified by the full-bridge rectifier diode, and the voltage all becomes a positive-phase voltage. However, the voltage obtained at this time still has large fluctuations, which requires the use of high-voltage filter capacitors for preliminary voltage regulation, and the waveform is corrected to a waveform with smaller fluctuations.

The direct current is converted into high-frequency pulsating direct current, and this step is completed by the control circuit. The output part is fed back to the control circuit through a certain circuit, and the control circuit is used to adjust the switching time ratio of the high-frequency switching element to achieve the purpose of stabilizing the output voltage. The control circuit has been integrated at present, and various integrated circuits for switching power supplies have been made.

The obtained pulsating DC power is sent to a high-frequency switching transformer for step-down. The low-voltage filter circuit composed of diodes and filter capacitors is then rectified and filtered to obtain the pure and static low-voltage direct current used in the equipment.

In an ideal switching power supply, the power supply should work exactly as it was designed and modeled: providing a stable, smooth output voltage regardless of input, load or ambient temperature changes, and having 100% energy conversion efficiency. But the truth is, all components are imperfect: loads can vary, power supplies can be distorted, and environmental changes can affect performance. In addition, the need to increase performance, improve efficiency, reduce size, and reduce cost further increases the complexity of power supply designs.

The current development direction of switching power supply is high frequency, high reliability, low consumption, low noise, anti-interference and modularization, among which the key technology is high frequency, improving the loss of secondary rectifier devices.